What is Aluminium Surface Treatment Methods and Their Benefits?

The proper treatment of aluminium surfaces is crucial in various industries. Aluminium Surface Treatment Methods enhance durability, aesthetics, and function. According to a report by MarketsandMarkets, the global aluminium surface treatment market is projected to reach USD 5.9 billion by 2025. This underscores the growing importance of effective treatment processes.

Aluminium is widely used in construction, automotive, and aerospace sectors due to its lightweight and corrosion resistance. Yet, without treatment, aluminium can degrade quickly. Anodizing, powder coating, and chemical treatments are common methods that improve performance. These methods can increase lifespan by more than 50%. However, choosing the right treatment remains a challenge for many manufacturers.

While the benefits are clear, the processes need careful attention. Misapplication can lead to inconsistent results. For instance, inadequate surface preparation might hinder adhesion, compromising the protective layer. Understanding Aluminium Surface Treatment Methods is vital. Companies must weigh the pros and cons of each method to ensure quality and reliability in their products.

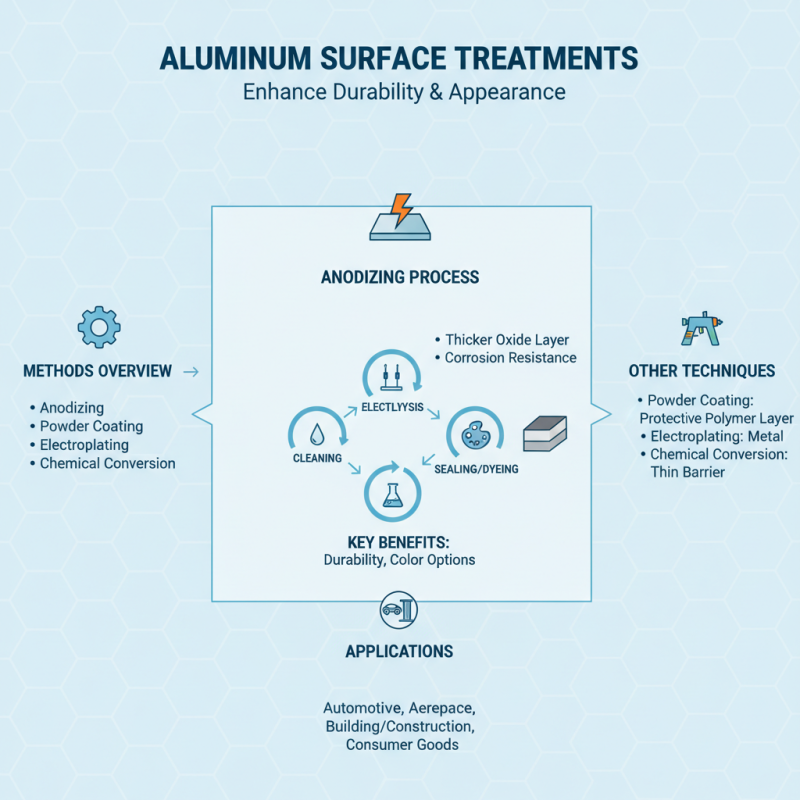

Aluminium Surface Treatment Methods: An Overview of Techniques

Aluminium surface treatment methods are crucial for enhancing the durability and appearance of aluminium products. There are several techniques available. Anodizing is a common method that increases corrosion resistance. This process creates a thicker oxide layer on the surface. It can also be dyed to improve aesthetics.

Another approach is powder coating. This technique applies a dry powder that is cured under heat. Powder coating is known for its vibrant colors and superior finish. It provides excellent protection against scratches and fading. However, the process requires careful surface preparation, which can be challenging.

Milling and polishing are traditional methods. They give an attractive sheen to aluminium parts. While these methods improve appearance, they may not significantly enhance durability. They are often labor-intensive, leading to higher costs. In some cases, the results can be inconsistent, requiring further refinements. Each method has its advantages and drawbacks, making it vital to choose the right one for specific applications.

Anodizing Aluminium: Process, Types, and Advantages Explained

Anodizing aluminium

is a popular surface treatment method. This process enhances the metal's resistance to corrosion and wear. It involves using an electrolytic passivation process to create a thick oxide layer on the surface. This layer can significantly improve durability, extending the product's lifespan. Reports suggest that anodized aluminium can last up to 20 years longer than untreated aluminium in harsh conditions.

There are various types of anodizing, including sulfuric, hard coat, and chromic anodizing. Sulfuric anodizing is the most common and provides a good balance of cost and performance. Hard coat anodizing offers increased abrasion resistance. Each type suits different applications based on environmental conditions and desired outcomes.

Tips: When selecting an anodizing method, consider environmental factors such as humidity and exposure to chemicals. Different anodizing types offer unique advantages. Always test a sample before large-scale application to ensure the right choice. Remember, while anodizing improves performance, it may not be foolproof against extreme conditions. Regular maintenance is essential for optimal results.

Chemical Conversion Coating: Benefits and Application in Defence

Chemical conversion coating is an essential process for aluminium surfaces, especially in the defence sector. This method provides a protective layer through a chemical reaction that modifies the aluminium surface. The resulting coating enhances corrosion resistance significantly. It also improves adhesion for paints and other coatings. This combination makes it ideal for military applications, where durability is crucial.

One notable benefit is the lightweight nature of this treatment. It does not add significant weight, which is vital in aerospace and defence industries. The environmental aspects are appealing too. Chemical conversion coatings often involve non-toxic materials, reducing harmful impacts. However, achieving a uniform coating can be challenging. Variability in process conditions might lead to inconsistent results. This requires careful monitoring and adjustment to maintain quality standards. In this regard, teams must remain vigilant and proactive.

The application of such coatings in defence goes beyond aesthetics. They provide critical protection against harsh environments. Yet, the treatment must be carefully tailored to specific uses. Each scenario may present unique challenges. It is essential to consider factors such as altitude, humidity, or exposure to various chemicals. A one-size-fits-all approach could fall short. Thus, ongoing research and development are necessary to address these issues effectively.

What is Aluminium Surface Treatment Methods and Their Benefits?

| Method | Benefits | Applications in Defence |

|---|---|---|

| Chemical Conversion Coating | Corrosion resistance, Improved paint adhesion, Minimal thickness | Aircraft components, Military vehicles, Equipment housings |

| Anodizing | Enhanced durability, Increased wear resistance, Aesthetic finish | Weapon systems, Defence electronics, Armor plating |

| Powder Coating | High UV and corrosion resistance, Durable finish, Various colors | Military vehicles, Support structures, Ground equipment |

| Electropolishing | Smooth surface finish, Enhanced corrosion resistance, Easy to clean | Sensitive equipment, Communications gear, Electronic housings |

Mechanical Finishing Techniques for Aluminium: Methods and Outcomes

Mechanical finishing techniques play a crucial role in aluminium surface treatment. They enhance both appearance and performance. Common methods include grinding, polishing, and bead blasting. Each technique offers unique benefits and finishes.

Grinding removes surface imperfections and prepares the aluminium for further treatment. It’s effective but can lead to uneven surfaces if not done carefully. Polishing creates a bright, reflective surface. However, achieving a consistent shine requires skill and patience. Bead blasting delivers a matte finish and improves adhesion for coatings. Yet, it may not be suitable for all applications.

While these methods are beneficial, they come with challenges. Improper execution can result in scratches or surface damage. It's essential to balance quality and efficiency. Regular evaluation of the finished product is necessary to ensure high standards are maintained. Each technique demands practice and attention to detail. The right method depends on the desired outcome and the specific application of the aluminium product.

Aluminium Surface Treatment Methods and Their Benefits

Comparison of Surface Treatment Methods: Cost, Durability, and Applications

Aluminium surface treatment methods vary widely in cost, durability, and applications. Common processes include anodizing, painting, and powder coating. Each method offers distinct benefits and trade-offs. Anodizing enhances corrosion resistance and hardness but can be more expensive. Reports indicate that anodized surfaces can last two to four times longer than untreated aluminium, depending on environmental factors.

Painting is the most cost-effective option but may require frequent touch-ups. It typically lasts 5-10 years. Powder coating, while pricier, provides a robust finish that resists scratches and UV degradation. Studies show that powder-coated surfaces outperform conventional paint in lifespan and durability, often exceeding 10-15 years.

Tips: When selecting a treatment method, consider the environmental conditions your product will face. For projects with tight budgets, painting might suffice. For long-term investments, anodizing or powder coating may be worth the extra cost. Always assess the total cost of ownership, not just initial expenses.

Related Posts

-

2026 Top Trends in Aluminium T Slot Profile Systems What You Need to Know?

-

How to Choose Aluminium Profile Wall Cladding for Your Project?

-

How to Choose the Best Aluminium Profile for Doors and Windows Installation

-

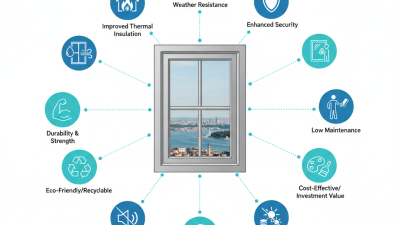

Top 10 Benefits of Choosing Aluminium Windows in Turkey for Your Home

-

2026 Top Aluminium Profile For Doors And Windows Trends to Watch?

-

Top 10 Aluminium Door China Options for Your Home?