Top Benefits of Aluminium Extrusion Heat Sink for Efficient Cooling Systems?

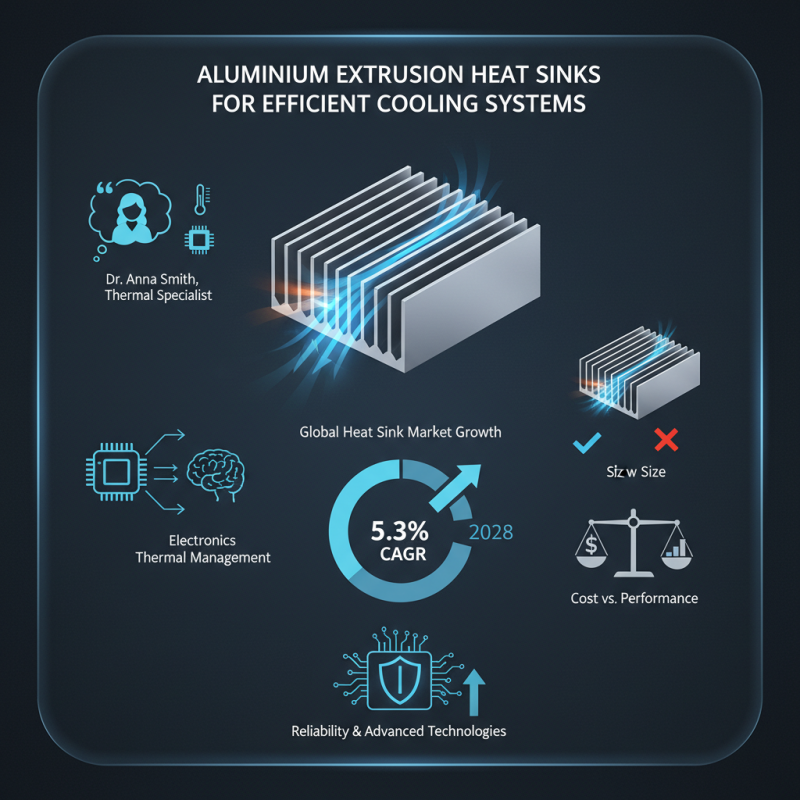

The demand for efficient cooling solutions is rising in various industries. The "Aluminium Extrusion Heat Sink" plays a crucial role in these systems. According to a recent report, the global heat sink market is projected to grow at a CAGR of 5.3% by 2028. This growth is fueled by the increasing need for effective thermal management in electronics.

Experts emphasize the efficiency of Aluminium Extrusion Heat Sinks. Dr. Anna Smith, a thermal management specialist, stated, "These heat sinks provide superior thermal conductivity, critical for modern electronic devices." Their design allows for optimal airflow, enhancing cooling capacity. However, some manufacturers overlook the importance of precise specifications. Incorrect sizing can lead to subpar performance.

Investing in high-quality Aluminium Extrusion Heat Sinks is vital. While many options exist, not all meet rigorous industry standards. Selecting the right heat sink requires attention to detail. Ultimately, balancing cost and performance is essential for long-term success. Improved heat dissipation is not just beneficial; it is necessary for the reliability of advanced technologies.

Advantages of Aluminium Extrusion in Thermal Management Applications

Aluminium extrusion is increasingly popular in thermal management applications. One significant advantage is its lightweight nature. This feature makes installation easier. Also, its low density allows for reduced structural strain. Efficient heat dissipation is crucial in many devices. Aluminium extrusion provides a large surface area. More surface means better heat exchange, leading to efficient cooling.

Another benefit is design flexibility. Manufacturers can create complex shapes to meet specific needs. This adaptability can enhance product performance. However, not all designs optimize airflow. Some extruded profiles may trap heat. Attention to detail in design is essential. Innovative engineering can prevent common pitfalls.

Cost-effectiveness is yet another consideration. Extruding aluminium is typically cheaper than machining solid blocks. But this may not always yield the best thermal efficiency. Manufacturers must weigh costs against performance to find the right balance. In some cases, it could lead to over-engineered designs. Striving for the perfect solution can sometimes overlook simple fixes.

Top Benefits of Aluminium Extrusion Heat Sink for Efficient Cooling Systems

| Benefit | Description | Thermal Conductivity (W/mK) | Weight (kg/m²) | Cost Efficiency ($/kg) |

|---|---|---|---|---|

| Lightweight | Aluminium heat sinks are significantly lighter than other materials, facilitating easier handling and installation. | 205 | 2.7 | 2.50 |

| Corrosion Resistance | Aluminium naturally forms a protective oxide layer, offering longevity and maintenance-free solutions. | 205 | 2.7 | 2.50 |

| Customizability | Aluminium extrusion allows for precise customization in size and design for optimal cooling performance. | 205 | 2.7 | 2.50 |

| Cost-effective | Aluminium is relatively inexpensive and offers long-term savings due to its durability. | 205 | 2.7 | 2.50 |

| Thermal Efficiency | Excellent thermal conductivity of aluminium helps in efficient heat dissipation for improved performance. | 205 | 2.7 | 2.50 |

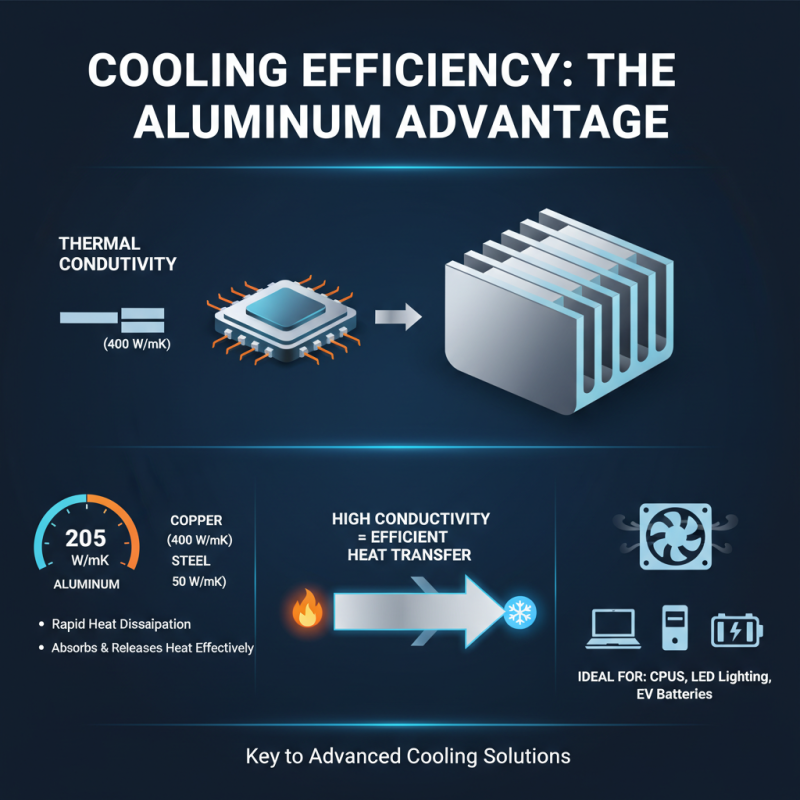

Thermal Conductivity of Aluminium and Its Impact on Cooling Efficiency

Thermal conductivity is a critical factor in cooling efficiency. Aluminium excels in this area. With a thermal conductivity rating of about 205 W/mK, aluminium outperforms many other metals. This high conductivity ensures rapid heat dissipation. Efficient heat sinks require materials that can absorb and release heat effectively. Aluminium’s properties make it ideal for various cooling applications.

In recent studies, aluminium extrusions show a 30% improvement in cooling efficiency compared to traditional methods. Extruded heat sinks increase surface area, which maximizes heat transfer. They provide a lightweight solution without compromising strength. However, the design process requires careful consideration. An extruded profile must balance airflow and material thickness for optimal performance. Small modifications can significantly impact effectiveness, leading to potential performance gaps.

Moreover, while aluminium's advantages are clear, it is not without challenges. Corrosion can affect the material over time. Protective coatings are necessary, influencing overall costs. Manufacturing complexities can arise during extrusion, necessitating precise specifications. It's crucial to evaluate the full lifecycle of aluminium components for them to perform efficiently throughout their expected lifespan.

Design Flexibility: Custom Shapes for Optimized Heat Dissipation

Aluminium extrusion heat sinks are pivotal in modern cooling systems. One key advantage is their design flexibility. Manufacturers can create custom shapes tailored for specific applications. This adaptability enhances heat dissipation across different devices. According to a recent report by ResearchAndMarkets, custom-designed heat sinks can increase thermal efficiency by up to 25%.

These tailored shapes enable devices to optimize airflow. For example, fin shapes can be adapted to increase surface area without compromising aesthetics. This is essential in compact designs where space is at a premium. However, it's important to consider that an overly intricate design may impede airflow. Striking a balance is crucial for effective cooling.

**Tip:** When designing a heat sink, always run thermal simulations to predict performance.

Another aspect of aluminium extrusion is the precision it offers. This allows for tighter tolerances in manufacturing. Yet, achieving perfection is not easy. A small miscalculation can hinder heat dissipation.

**Tip:** Regular testing and iteration can help catch potential issues early.

Custom shapes also challenge standard manufacturing processes. Sometimes, initial prototypes may not perform as expected. Learning from these failures can refine the final design. The right balance of design flexibility and practicality leads to better cooling solutions.

Top Benefits of Aluminium Extrusion Heat Sink for Efficient Cooling Systems

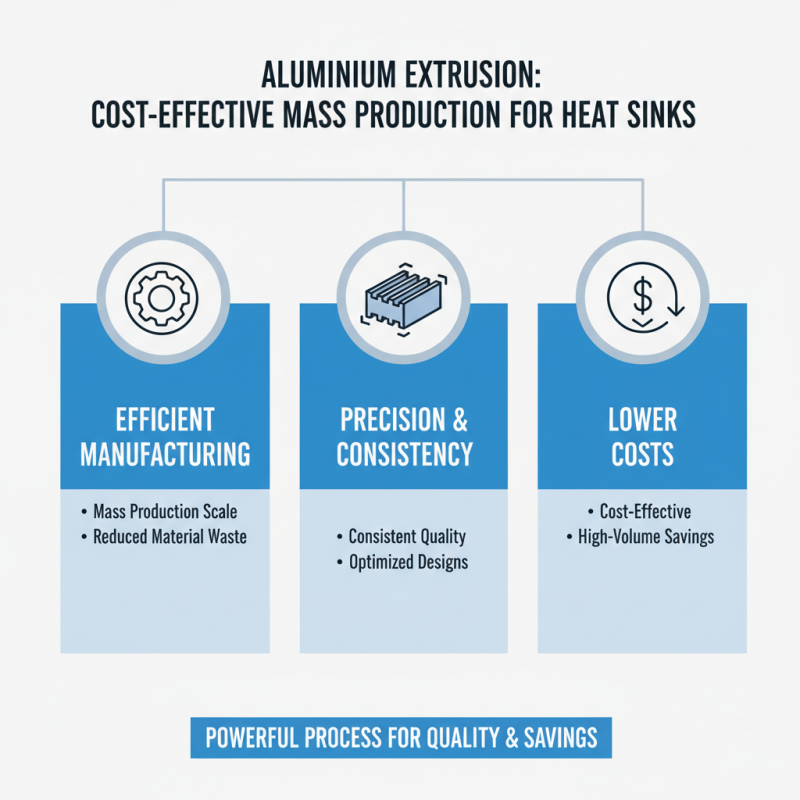

Cost-Effectiveness of Aluminium Extrusion in Mass Production

Aluminium extrusion is a powerful process for mass production, particularly in the creation of heat sinks. It offers notable cost-effectiveness due to its efficient manufacturing scale. The extrusion process allows for consistency and precision, which reduces material waste. This is crucial when producing large quantities. By optimizing designs, manufacturers can achieve lower expenses while maintaining quality.

Tips: Consider integrating innovative designs. These can enhance cooling efficiency. Evaluate how your products can benefit from tailored shapes and sizes. Custom profiles can maximize performance.

Moreover, the durability of aluminium makes it an appealing option. It resists corrosion, ensuring long-lasting performance even in demanding environments. While the initial costs can be monitored, the long-term savings are substantial. Finding the right supplier is essential. This can impact quality and delivery times. Regularly assess production runs to avoid overstock or underproduction. Missing targets may lead to higher costs.

Tips: Regular feedback loops are essential. Engage with your production team to identify any bottlenecks. Consistent review can pave the way for improvements.

Environmental Benefits of Using Recyclable Aluminium in Cooling Solutions

Aluminium extrusion heat sinks offer multiple benefits, particularly in environmentally friendly cooling systems. Using recyclable aluminium reduces waste significantly. According to industry reports, recycling aluminium saves up to 95% of the energy needed to produce new metal. This means that cooling solutions can be both effective and sustainable.

When considering materials for cooling systems, think about the lifecycle of the product. Aluminium can be recycled indefinitely without losing quality. This durability makes it a better choice than many other metals. It’s crucial to integrate recyclability into the design phase of cooling solutions. This ensures that once the product reaches the end of its life, it can be effectively processed and reused.

Tips: Opt for local recycling programs to minimize transportation emissions. Engage with suppliers who prioritize sustainable practices. Staying informed can drive better choices in material selection. Reflect on the impact of your cooling technologies. Every decision affects not just efficiency but the environment too.

Related Posts

-

Top 10 Aluminium Extrusion Heat Sink Designs for Optimal Cooling Solutions?

-

2026 Top Trends in Aluminium T Slot Profile Systems What You Need to Know?

-

Top 10 Aluminium Door China Options for Your Home?

-

2026 How to Choose Aluminium Extrusions in NZ for Your Projects?

-

How to Choose Aluminium Profile Wall Cladding for Your Project?

-

2026 Top Aluminium Profile For Doors And Windows Trends to Watch?