2026 Best Aluminium Extrusions in NZ for Your Next Project?

When planning a project, choosing the right materials is crucial. Among the options available, Aluminium Extrusions NZ stands out for its versatility and durability. These extrusions are not only lightweight but also highly customizable for various applications. From architectural designs to industrial uses, their adaptability makes them a preferred choice.

In 2026, the landscape for Aluminium Extrusions NZ is set to evolve. New technologies and trends emerge, pushing the boundaries of design and functionality. This guide explores the best aluminium extrusions available, catering to different needs and budgets. Yet, it’s essential to reflect on what truly matters.

Quality does not come without a cost. Consumers might face challenges in finding the right supplier. The wide range of options can also be overwhelming. As you embark on your next project, consider the long-term benefits. Balancing aesthetics and performance is key. Aim for practical solutions that do not compromise on style.

The Importance of Aluminium Extrusions in Modern Construction Projects

Aluminium extrusions have become vital in modern construction. They provide both strength and flexibility, making them ideal for a variety of applications. According to a report by Research and Markets, the global aluminium extrusion market is projected to reach $1.5 trillion by 2025. This growth reflects the increasing demand for lightweight and durable materials in building projects.

The advantages of aluminium extrusions are numerous. They can be customized to meet specific project needs. Architects appreciate the versatility. However, challenges exist. Recycling processes are not always efficient, leading to increased waste. A survey from the Aluminium Association found that 36% of industry professionals cite sustainability as a key concern in their projects. This highlights the need for better practices in the industry.

Moreover, while aluminium is corrosion-resistant, improper care during installation can lead to issues later. Ensuring proper sealing and coatings is essential. The Schneider Group reported that about 20% of construction failures are linked to material performance. Thus, attention to detail in the use of aluminium extrusions is critical in construction success.

Key Features to Consider When Choosing Aluminium Extrusions in NZ

When selecting aluminium extrusions in New Zealand, several key features are critical to consider. The alloy type plays a crucial role in determining strength and corrosion resistance. Alloys like 6060 and 6061 are common choices. They offer good workability and excellent mechanical properties. According to industry reports, 6061 is known for its high strength and better extrudability. This alloy is often used in structural applications.

Another important feature is the surface finish. Powder coating and anodizing can enhance the durability of aluminium extrusions. These finishes not only improve aesthetics but also protect against environmental factors. Data suggests that properly anodized aluminium can last up to 30 years without significant degradation. However, choosing the right finish depends on the project's specific environmental conditions.

Sizing and tolerance are also vital. Each project may require different dimensions and specifications. While standard sizes are available, custom extrusions can be more costly. Many projects overlook the need for precision, leading to potential adjustments and delays. It's essential to communicate specific requirements clearly to avoid unnecessary setbacks. Balancing cost and quality is a continuous challenge in the selection process.

2026 Best Aluminium Extrusions in NZ

Top Manufacturers of Aluminium Extrusions in New Zealand for 2026

When considering the best aluminium extrusions for your next project in New Zealand, it's essential to know where to find quality manufacturers. The local industry offers a diverse range of options. Many manufacturers specialize in various sectors, including construction, automotive, and electronics. Researching these companies can provide you insights into their capabilities and product offerings.

Quality is often a mixed bag. Some manufacturers excel in design but struggle with timely delivery. Others might offer superb customer service but lack the product variety. It’s vital to evaluate each manufacturer carefully. Customer reviews can reveal a lot about their experience. Consider reaching out for quotes and samples to truly assess which company aligns with your project’s needs.

Another aspect to ponder is sustainability. Many manufacturers now focus on eco-friendly practices. However, not all claim to be sustainable truly deliver on that promise. Assessing the carbon footprint of your chosen supplier could make a difference. It’s about making informed choices today that impact the environment tomorrow.

2026 Best Aluminium Extrusions in NZ for Your Next Project

| Dimension (mm) | Weight (kg/m) | Material Type | Finish Type |

|---|---|---|---|

| 50 x 50 | 1.55 | 6060 | Anodized |

| 40 x 20 | 0.92 | 6063 | Powder Coated |

| 75 x 75 | 2.10 | 6005 | Mill Finish |

| 30 x 30 | 0.61 | 6060 | Brushed |

| 20 x 10 | 0.40 | 6063 | Anodized |

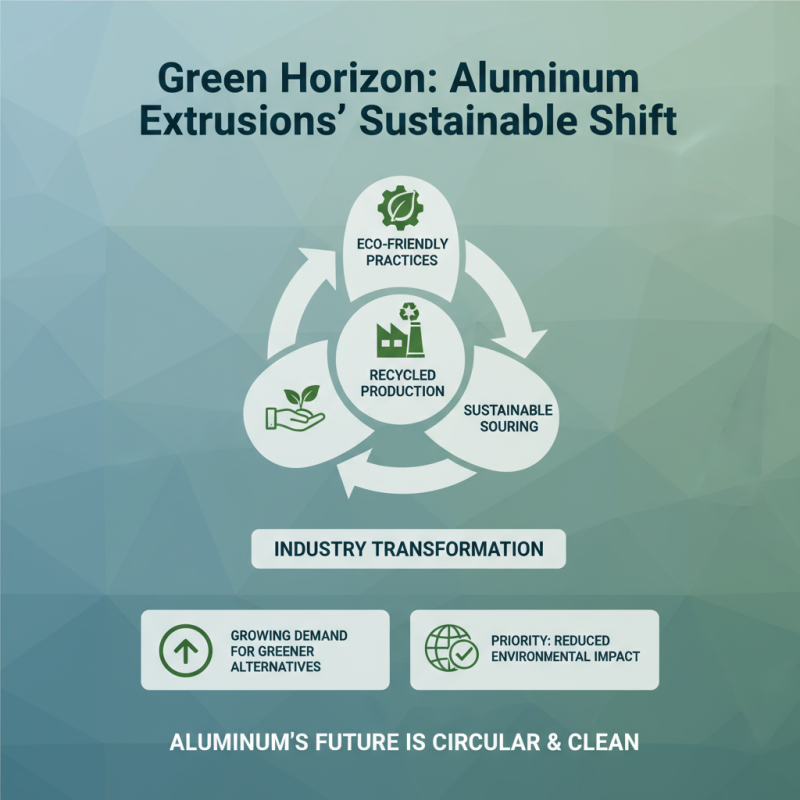

Sustainability and Recycling Trends in Aluminium Extrusions Industry

The aluminium extrusions industry is undergoing significant changes with a focus on sustainability and recycling. Many companies are now turning to more eco-friendly practices. They are reevaluating their production processes. Sustainable sourcing of materials is becoming a priority. This is crucial as the demand for greener alternatives grows.

Recycling trends in aluminium extrusions are also noteworthy. Aluminium can be recycled multiple times without losing its properties. This ensures less waste and a reduced carbon footprint. However, the industry still faces challenges. Not all facilities have efficient recycling systems in place. Some companies might struggle to meet their sustainability goals due to lack of infrastructure.

The adoption of recycled aluminium in new extrusions is gaining traction. It reduces energy consumption significantly. Yet, the overall percentage of recycled content in products often remains lower than desired. Many industry players acknowledge that there’s still room for improvement. To truly lead in sustainability, a collective effort is essential. It requires innovation, investment, and a commitment to change.

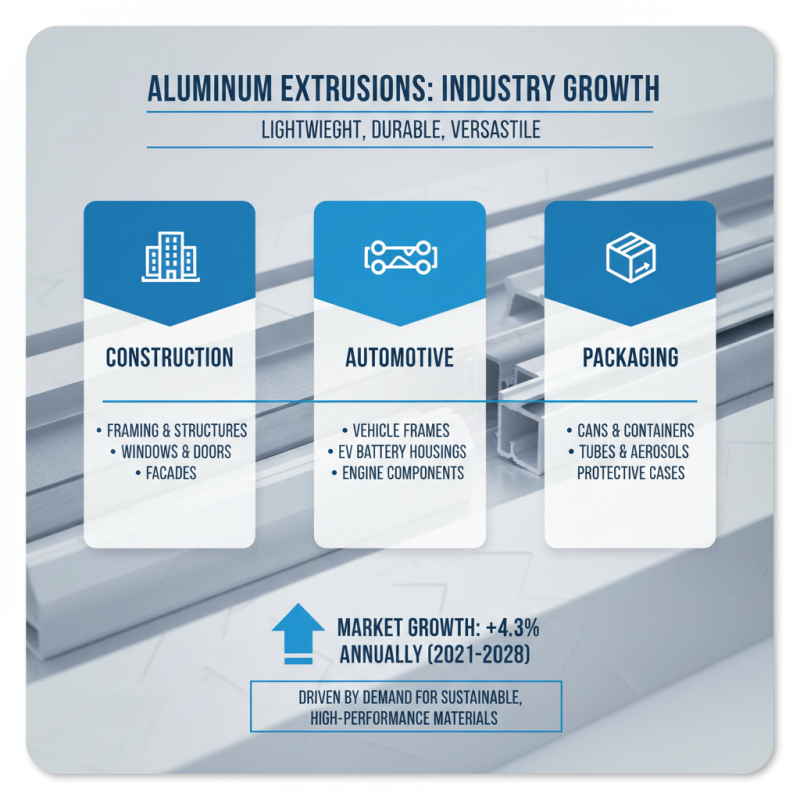

Innovative Applications of Aluminium Extrusions in Various Industries

Aluminium extrusions play a vital role across various industries. They are increasingly used in construction, automotive, and packaging. According to a recent market report, the aluminium extrusion market is expected to grow by 4.3% annually from 2021 to 2028. This growth reflects a rising demand for lightweight materials with excellent durability.

In construction, aluminium extrusions are favored for their ability to create complex shapes. They offer high strength-to-weight ratios. Structures can be lighter and more robust. The automotive industry utilizes these extrusions for efficient body parts. The reduction in weight improves fuel efficiency. Surprisingly, some companies still underestimate the full potential of these materials.

Packaging remains another innovative area. Aluminium is recyclable and adds significant value to products. However, many manufacturers struggle to integrate sustainability effectively into their processes. This is a reminder that despite aluminium's advantages, some practices need reevaluation. Technical challenges still exist, limiting innovation. Addressing these issues can enhance application effectiveness and ensure wider adoption in industry.

Related Posts

-

10 Essential Tips for Choosing Aluminium Extrusions in NZ

-

What is Aluminium Surface Treatment Methods and Their Benefits?

-

Why Choose Aluminium Heat Sink Material for Efficient Thermal Management?

-

2026 How to Optimize the Aluminium Process for Maximum Efficiency?

-

2026 Top Aluminium Profile For Doors And Windows Trends to Watch?

-

2026 Top Trends in Aluminium T Slot Profile Systems What You Need to Know?