2026 How to Choose Aluminium Extrusions in NZ for Your Projects?

When embarking on a project in New Zealand, selecting the right aluminium extrusions NZ is crucial. The choice can significantly impact the success and functionality of your design. Many factors come into play, including strength, weight, and finish. Ignoring these details can lead to unnecessary complications down the line.

Why does it matter? Aluminium extrusions NZ offer versatility and durability, making them popular in various applications. Whether for construction or manufacturing, the right selection can enhance your project. Consider the project's specific needs carefully. A misstep in choosing the material can result in wasted time and resources.

Moreover, not all suppliers provide the same quality. Take the time to research and compare options. Speak with industry professionals and gather insights. This process may seem tedious, but it is essential for achieving the best possible results. Reflect on your choices, and don’t hesitate to seek guidance. Quality aluminium extrusions NZ can elevate your project in ways you might not initially consider.

Understanding Aluminium Extrusions: Key Concepts and Benefits

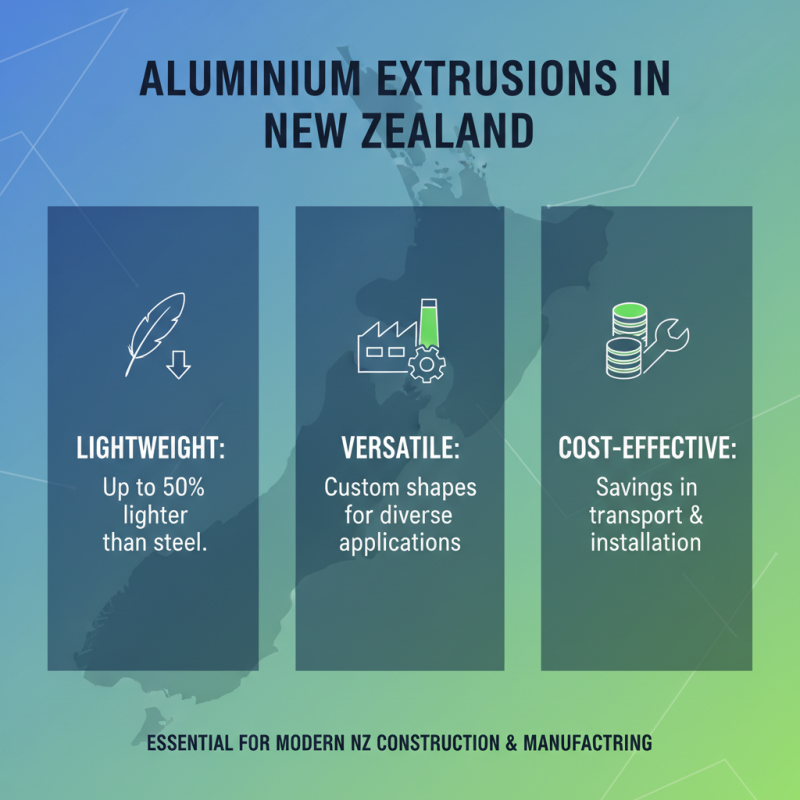

Aluminium extrusions are becoming essential in construction and manufacturing in New Zealand. Understanding their key concepts and benefits is crucial. For example, the lightweight nature of aluminium makes it ideal for structures where weight is a concern. According to a recent industry report, aluminium extrusions can save up to 50% in weight compared to traditional materials like steel. This advantage often leads to cost savings in transport and installation.

Moreover, aluminium is highly resistant to corrosion, which increases its longevity. Research indicates that materials exposed to extreme environments can endure over 60 years without significant degradation. This durability is essential for projects that aim for sustainability. However, there are considerations to keep in mind. Not all aluminium alloys are suitable for every application, and choosing the wrong type can lead to project setbacks.

Additionally, while aluminium is recyclable, it is still important to assess the environmental impact of sourcing and processing it. Striking a balance between cost efficiency and sustainability principles can be challenging. It's essential to engage with knowledgeable suppliers when making these choices to avoid pitfalls. Awareness of the specific properties of each extrusion type is key to successful project completion.

Factors to Consider When Selecting Aluminium Extrusions

When selecting aluminium extrusions for your projects in New Zealand, there are key factors to consider. The application is crucial. Will the aluminium be used for structural components or decorative elements? This decision impacts the extrusion profile you choose. Different projects require different tolerances and strengths.

Material quality is another important aspect. Not all aluminium is created equal. Ensure you understand the aluminium alloy's properties and suitability for your specific needs. Pay attention to the finish as well. A good surface treatment can enhance durability and aesthetics. However, options like anodizing or powder coating can add to your budget.

Cost is an inevitable factor. Some may opt for cheaper solutions without considering long-term performance. This could lead to higher maintenance costs later.

Weight matters too, especially for transport or installation. Sometimes lighter extrusions appear attractive but compromise strength. Balance is essential in your overall planning. Reflect on your project's requirements before making a final decision.

Different Types of Aluminium Extrusions Available in NZ

When choosing aluminium extrusions in New Zealand, understanding the available types is crucial. There are several options to consider. Common profiles include angles, channels, and tubes. Each serves a different purpose. For instance, angles are great for framing, while channels provide structural support. Tubes are often chosen for their strength and versatility.

Tip: Consider the specific application for your project. Are you looking for lightweight components? Or do you require something more durable? Each type of profile can impact your project's outcome.

Another important aspect is the finish of the extrusion. Anodized, powder-coated, or mill finish options can affect both aesthetics and durability. Anodizing adds a protective layer, while powder coating offers various colors. Mill finish exposes the raw aluminium, which may be more susceptible to wear.

Tip: Don’t overlook the environmental factors. UV exposure and moisture can influence your choice. Reflect on how these elements may affect your extrusions over time. Always think long-term for better results.

Applications of Aluminium Extrusions in Various Industries

Aluminium extrusions are widely used across various industries due to their versatility. In the construction sector, they provide structural support. They are lightweight, yet strong, making them ideal for window frames and roofing systems. The ability to customize extrusions means perfect fits for different architectural designs.

In the automotive industry, aluminium extrusions are essential for lightweight vehicle components. Reducing weight improves fuel efficiency and performance. However, some manufacturers struggle with balancing strength and weight. It’s important to minimize defects during production. Even minor imperfections can lead to significant issues later.

The electronics industry also benefits from aluminium extrusions. They are often used in heat sinks and enclosures. The thermal conductivity aids in managing heat effectively. Yet, determining the right thickness can be tricky. Too thin, and they may warp; too thick, and they add unnecessary weight. This requires careful consideration and testing.

2026 How to Choose Aluminium Extrusions in NZ for Your Projects? - Applications of Aluminium Extrusions in Various Industries

| Industry | Application | Common Alloy Types | Key Benefits |

|---|---|---|---|

| Construction | Window Frames & Structural Support | 6063, 6061 | Durability, Lightweight, Corrosion Resistance |

| Automotive | Chassis Components & Body Frames | 6061, 7075 | Lightweight, High Strength, Recyclable |

| Aerospace | Airframe Structures & Components | 2024, 7075 | High Strength-to-Weight Ratio, Fatigue Resistance |

| Electronics | Heat Sinks & Enclosures | 6060, 6063 | Thermal Conductivity, Lightweight, Aesthetic |

| Marine | Boat Frames & Decks | 5083, 5086 | Corrosion Resistance, High Strength, Lightweight |

Sourcing and Suppliers of Aluminium Extrusions in New Zealand

When sourcing aluminium extrusions in New Zealand, you have several options. Local suppliers often provide a range of profiles suitable for various projects. It's important to visit suppliers to examine their inventory. This allows you to assess the quality and pricing directly. Consider reaching out to multiple sources to gather quotes and compare them.

Partnerships with local manufacturers can also benefit your project. Building a relationship with a supplier can lead to better prices and faster service. Some suppliers may even offer custom extrusion services, but be aware of potential delays. Not every supplier will have the perfect fit for your needs. Be prepared for some trial and error in finding the right match.

Always check the supplier’s reputation through online reviews or industry referrals. A few negative reviews can be a red flag. Ensure they have experience in the particular type of extrusion you require. Look for certifications that guarantee quality standards. This is crucial for ensuring the integrity of your project.

Aluminium Extrusions Usage in Different Industries in New Zealand

Related Posts

-

10 Essential Tips for Choosing Aluminium Extrusions in NZ

-

2026 Best Aluminium Extrusions in NZ for Your Next Project?

-

Why Choose Aluminium Heat Sink Material for Efficient Thermal Management?

-

2026 How to Optimize the Aluminium Process for Maximum Efficiency?

-

How to Choose the Best Aluminium Profile for Doors and Windows Installation

-

What is Aluminium Surface Treatment Methods and Their Benefits?