How to Choose the Right Aluminium Extrusion Grades for Your Project?

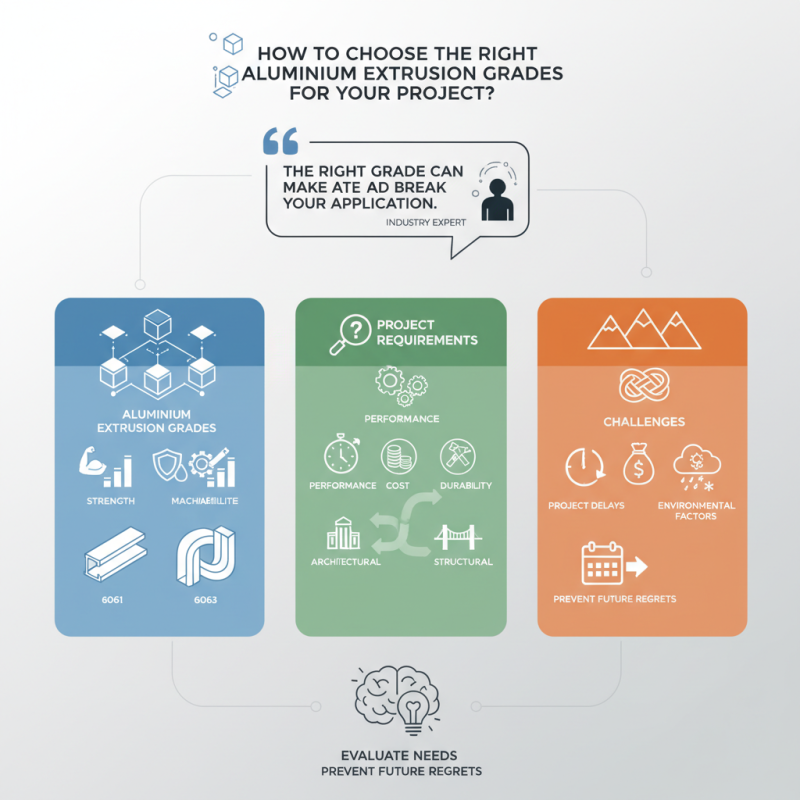

Choosing the right Aluminium Extrusion Grades is crucial for the success of any project. Industry expert John Smith states, "The right grade can make or break your application." With various options available, understanding the properties of each grade is essential. The choice can impact performance, cost, and the overall durability of the final product.

Aluminium Extrusion Grades vary widely in terms of strength, corrosion resistance, and machinability. Some grades excel in specific applications, while others fall short. For instance, 6061 is commonly used for structural components due to its excellent mechanical properties. However, 6063 is often preferred for architectural applications because of its aesthetic finish. It's important to assess project requirements carefully.

In the pursuit of finding the best Aluminium Extrusion Grades, challenges can arise. Miscalculations can lead to project delays and increased costs. Not every grade will perform well in every environment. Therefore, taking the time to evaluate needs is necessary. Remember, the right decision today can prevent future regrets.

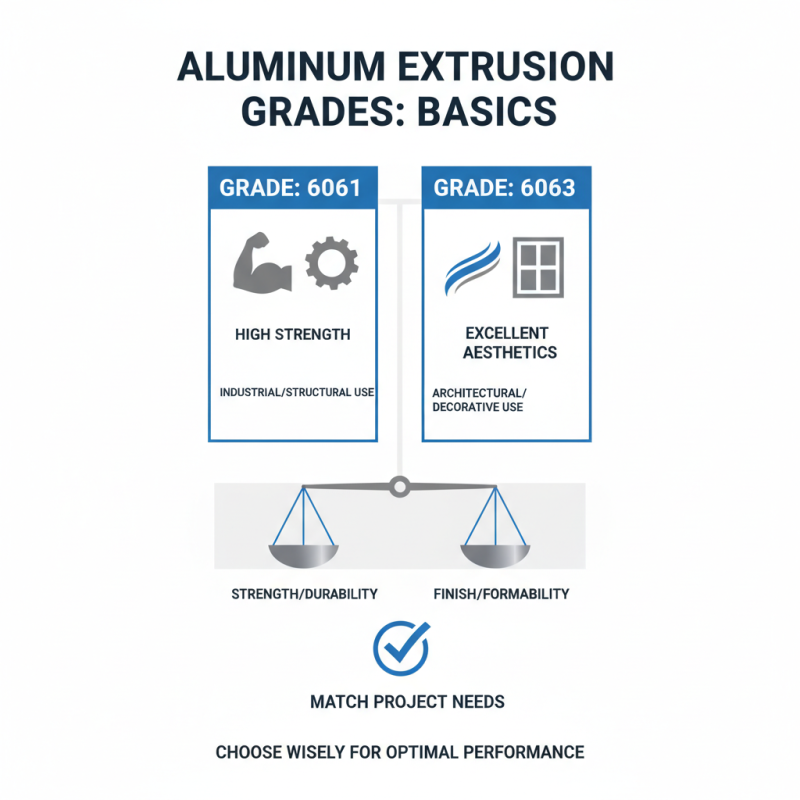

Understanding the Basics of Aluminium Extrusion Grades

When selecting aluminium extrusion grades for a project, understanding the basics is crucial. Aluminium grades differ in properties like strength, corrosion resistance, and workability. Common grades include 6061 and 6063. While 6061 offers high strength, 6063 provides excellent aesthetics. Knowing your project's requirements can guide you to the right choice.

Another key factor is the intended application. For structural components, a stronger grade such as 7075 might be more suitable. In contrast, ornamental pieces may benefit from the smoother finish of 6063. It’s essential to weigh these characteristics against your project's demands. Sometimes, the best decision might not be immediately clear, and trial and error might be necessary.

Cost is another aspect to consider. Higher grade aluminium tends to be more expensive. Balancing budget and performance can lead to tough decisions. Occasionally, the cheapest option might not meet strength requirements. Therefore, it’s worth reflecting on how each grade aligns with your project’s goals, and sometimes reconsidering your initial choices can lead to better outcomes.

Key Factors to Consider When Choosing Aluminium Extrusion Grades

Choosing the right aluminium extrusion grade is vital for project success. Various factors impact this decision. One critical aspect is the mechanical properties of the aluminium. For instance, the tensile strength can vary widely among different grades. A report by the Aluminium Association states that 6061 has a tensile strength of about 275 MPa, while 7075 can reach up to 570 MPa. These differences can influence the final application.

Another important factor is the corrosion resistance of the aluminium grade. For outdoor applications, selecting a grade with higher resistance to environmental elements is crucial. The 5005 grade, for example, offers excellent resistance to atmospheric corrosion and is often used in architectural applications. However, it’s essential to understand that not all grades perform equally well under specific conditions. This might lead to failures if overlooked.

Cost is also a significant element to consider. Different grades come with varying price tags. It is tempting to choose the less expensive option, but this decision can lead to unforeseen issues later. Balancing performance and budget can be challenging but is necessary. Data indicates that a good compromise can minimize costs without sacrificing quality. Keep in mind that choosing the wrong grade might not just escalate expenses but could also result in project delays. Consider this carefully when making your selection.

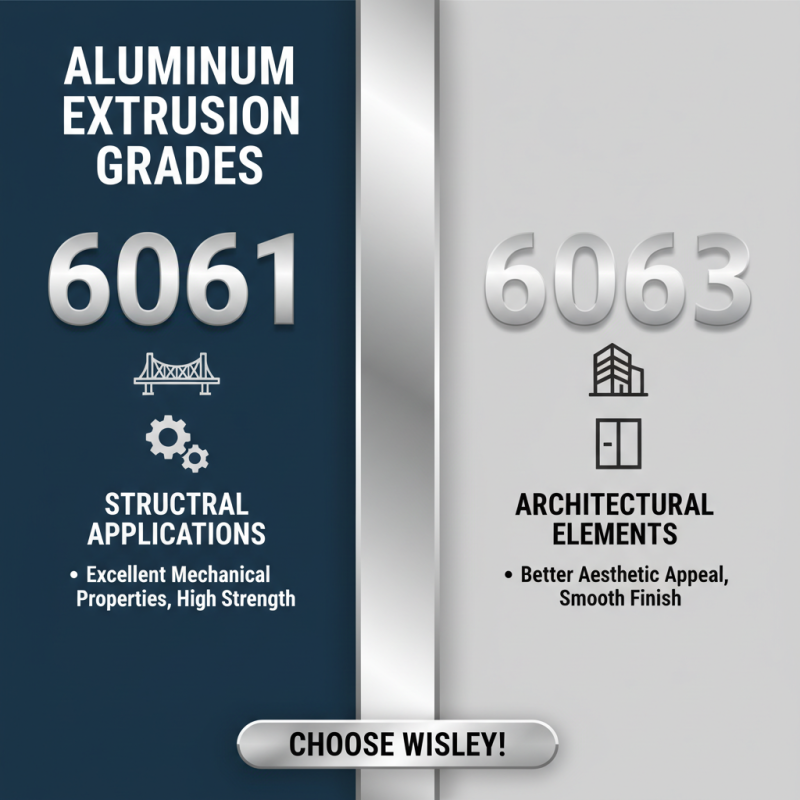

Comparing Common Aluminium Extrusion Grades and Their Applications

When selecting aluminium extrusion grades, understanding their unique properties is crucial. Some common grades include 6061 and 6063. Each has varying strengths and applications. For example, 6061 is known for its excellent mechanical properties. It is often used in structural applications. On the other hand, 6063 offers better aesthetic appeal and is ideal for architectural elements.

It's essential to consider the intended use. For high-stress applications, 6061 is the preferred choice. It withstands heavy loads and offers durability. Conversely, if the design's appearance matters, 6063 is more suitable. Its smooth surface finish is appealing for visible parts.

Sometimes, the choice may not be straightforward. Factors like corrosion resistance and fabrication methods can complicate the decision. If you're unsure about a specific grade, consult with knowledgeable sources. Reflecting on these details can lead to a more informed choice.

Evaluating Mechanical Properties of Different Aluminium Grades

Choosing the right aluminium extrusion grade can significantly impact project success. Each aluminium grade possesses unique mechanical properties, which dictate its suitability for various applications. For instance, grade 6061 is known for its excellent corrosion resistance and good weldability. It offers a tensile strength of around 310 MPa. This makes it ideal for structural components.

In contrast, grade 7075 is renowned for its high strength, boasting a tensile strength of approximately 570 MPa. This grade is preferred in aerospace applications but may not be as corrosion-resistant as 6061. Understanding these differences is crucial. Some projects may require high strength but can compromise on corrosion resistance. It's vital to evaluate the specific needs of your application.

Data from industry reports shows that many manufacturers overlook the importance of these properties. They frequently select aluminium grades based on cost rather than suitability. This can lead to product failures or increased maintenance costs. Consideration of mechanical properties should influence your selection process. Taking the time to analyze these aspects can save resources in the long run. It’s a reflection of smart engineering choices.

Mechanical Properties of Common Aluminium Extrusion Grades

Tips for Selecting the Right Aluminium Grade for Specific Projects

Choosing the right aluminium extrusion grade can be challenging. Different projects require different properties, and matching these needs is crucial. For instance, if you’re working on structural supports, you might need a strong, durable alloy. 6061 is popular for its strength and corrosion resistance, but it may not always be the best choice.

Consider the environment where the aluminium will be used. For projects exposed to harsh conditions, such as marine applications, a grade like 6063 may offer better resistance. It’s essential to think about factors like machinability and weldability too. Sometimes, it's easy to overlook these aspects in favor of strength alone.

You should also reflect on costs. Higher-grade alloys may come with a higher price tag. This could be a factor for budget-sensitive projects. Balancing the budget and requirements often leads to compromises. It’s vital to thoroughly review your project specifications before making a decision. Only then can you select the right aluminium grade that meets your needs effectively.

Related Posts

-

How to Choose the Best Aluminium Profile for Doors and Windows Installation

-

Ultimate Guide to Aluminium Profile Cladding Tips for Effective Installation

-

2026 Top Trends in Aluminium T Slot Profile Systems What You Need to Know?

-

Top 10 Benefits of Choosing Aluminium Windows in Turkey for Your Home

-

2026 How to Optimize the Aluminium Process for Maximum Efficiency?

-

How to Choose Aluminium Profile Wall Cladding for Your Project?