10 Essential Tips for Choosing Aluminium Extrusions in NZ

When considering Aluminium Extrusions NZ, it’s crucial to understand some key factors. The aluminium extrusion market in New Zealand is expected to grow significantly. According to industry reports, the demand for lightweight and durable materials is on the rise, particularly in construction and transportation. Choosing the right aluminium extrusion requires careful analysis and understanding of specific applications.

The properties of aluminium, such as excellent corrosion resistance and high strength-to-weight ratio, make it an appealing choice. However, not all extrusions are created equal. There are various profiles available, each suited for different needs and applications. Missteps in selection can lead to performance issues or increased costs.

Referencing the New Zealand market, many companies still lack awareness about the benefits of tailored aluminium extrusions. This gap can lead to overspending on generic solutions. As professionals in the field highlight, it’s vital to consider not only aesthetic qualities but also functional longevity. Being informed can significantly enhance project outcomes in a competitive landscape.

Understanding the Basics of Aluminium Extrusions in New Zealand

Aluminium extrusions are crucial in various industries in New Zealand. These lightweight, durable materials come in diverse shapes, making them versatile for numerous applications. According to recent industry data, the market for aluminium extrusions in New Zealand is projected to grow by 5% annually. This growth reflects the increasing demand for sustainable and energy-efficient materials.

Understanding the basics of aluminium extrusions is essential for making informed choices. They are typically produced through a process where aluminium is heated and forced through a die. This method creates profiles that can be used in construction, manufacturing, and transportation. However, not all extrusions are created equal. It's important to consider factors like alloy type, finish, and dimensions which can significantly impact performance and cost.

When selecting aluminium extrusions, one often overlooks quality standards. It's critical to verify compliance with New Zealand's specifications. A recent report highlighted that nearly 30% of extrusions do not meet the necessary regulations, resulting in delays and increased project costs. Buyers should prioritize transparency in sourcing and production. Invest time in research to avoid mistakes, as the initial choice can lead to substantial long-term consequences.

Identifying the Right Alloy for Your Project Needs

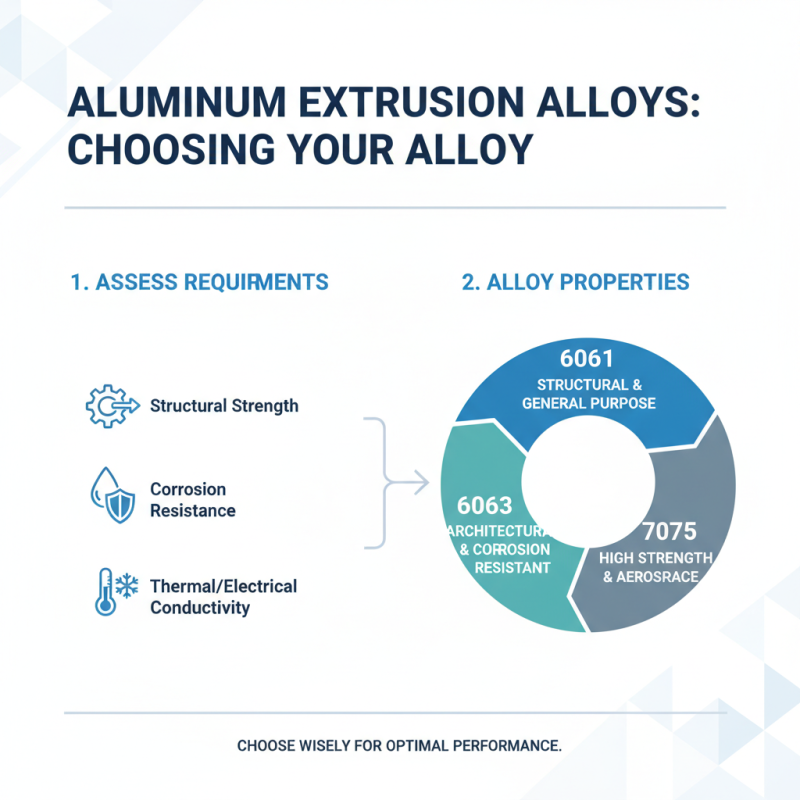

Choosing the right alloy for your aluminium extrusion project is critical. Begin by assessing your project’s specific requirements. Different alloys have unique properties. For instance, some alloys are better for structural applications, while others excel in corrosion resistance.

Tip: Gauge the environment. If your project is near water or chemicals, select an alloy with robust corrosion resistance.

Remember, strength matters too. Some alloys are more suitable for heavy loads, while others can bend easily. Consider the end-use of your product. Will it be exposed to stress or impact?

Tip: Test samples before finalizing. Sometimes, what seems perfect may not perform well under pressure. Testing helps you understand the material's limits and capabilities.

Pay attention to finishing options as well. An alloy may look great but underperform in specific finishes. An unsuitable finish could lead to failures. Evaluate how the alloy will react to processes like welding or anodizing.

Tip: Consult experts when unsure. It’s easy to overlook details. Professional advice can save time and resources.

Evaluating the Quality of Aluminium Extrusions Available

Choosing high-quality aluminium extrusions is crucial for any construction or manufacturing project. Evaluating the quality involves several factors. First, look for the aluminium alloy used. Common alloys in NZ include 6060, 6061, and 6082. According to industry reports, these alloys offer excellent corrosion resistance and good mechanical properties, making them ideal for various applications.

Next, consider the surface finish. Anodizing is popular for enhancing durability. A report from the Aluminium Association indicates that anodized finishes can increase resistance to wear by up to 20%. Check the thickness of the anodizing layer as it directly affects longevity. It’s also wise to look for certifications, such as ISO 9001, which indicate adherence to international quality standards.

Pay attention to the extrusion method. Different methods, such as direct or indirect extrusion, impact the material's structural integrity. A study found that materials from direct extrusion are usually stronger but can be more expensive. Additionally, some manufacturers may cut corners on quality, leading to air pockets or weak zones. Always request a quality assurance report to verify the extrusion quality. Remember, the wrong choice here could compromise your entire project.

10 Essential Tips for Choosing Aluminium Extrusions in NZ - Evaluating the Quality of Aluminium Extrusions Available

| Tip Number | Tip Description | Quality Indicator | Considerations |

|---|---|---|---|

| 1 | Assess the Alloy Type | Strength and Corrosion Resistance | Choose suitable alloys based on application needs. |

| 2 | Check the Anodizing Quality | Durability and Surface Protection | Look for consistent thickness and good adhesion. |

| 3 | Evaluate Surface Finish | Aesthetic Appeal and Functionality | Consider the finish type that matches your design. |

| 4 | Review Tolerances | Precision and Fit | Ensure tolerances meet your project specifications. |

| 5 | Consider Weight and Size | Handling and Structural Integrity | Match size and weight to project requirements. |

| 6 | Understand Cost vs. Quality | Value for Money | Balance budget with quality for optimal results. |

| 7 | Inspect for Defects | Assurance of Quality | Look for scratches, bends, or any irregularities. |

| 8 | Research Supplier Reputation | Reliability and Trustworthiness | Choose suppliers with a solid track record. |

| 9 | Consider Environmental Impact | Sustainability | Source from eco-friendly and sustainable practices. |

| 10 | Request Samples for Testing | Proof of Performance | Always test samples before making bulk purchases. |

Considerations for Custom vs Standard Extrusions

When selecting aluminium extrusions in New Zealand, the choice between custom and standard extrusions is crucial. Custom extrusions allow for unique dimensions and designs tailored to specific needs. Data from the Aluminium Extruders Council shows that about 60% of projects can benefit from custom profiles. However, the costs can be significant, leading some businesses to reconsider their options.

Standard extrusions, on the other hand, can offer faster turnaround times and lower costs. They are suitable for projects that do not require specific designs. The drawback here is the potential limitation in design flexibility. According to a recent industry report, nearly 40% of companies faced challenges meeting specific project requirements with standard profiles. This highlights the need for careful evaluation.

A well-thought-out approach can save time and money. Consider the volume and application of your project. If you’re looking at a large-scale production, investing in custom profiles might be worthwhile. For smaller projects, standard options may suffice. Always compare quotations and production times. Relying solely on one option may cause missed opportunities for your project needs.

Budgeting: Cost Factors in Aluminium Extrusion Selection

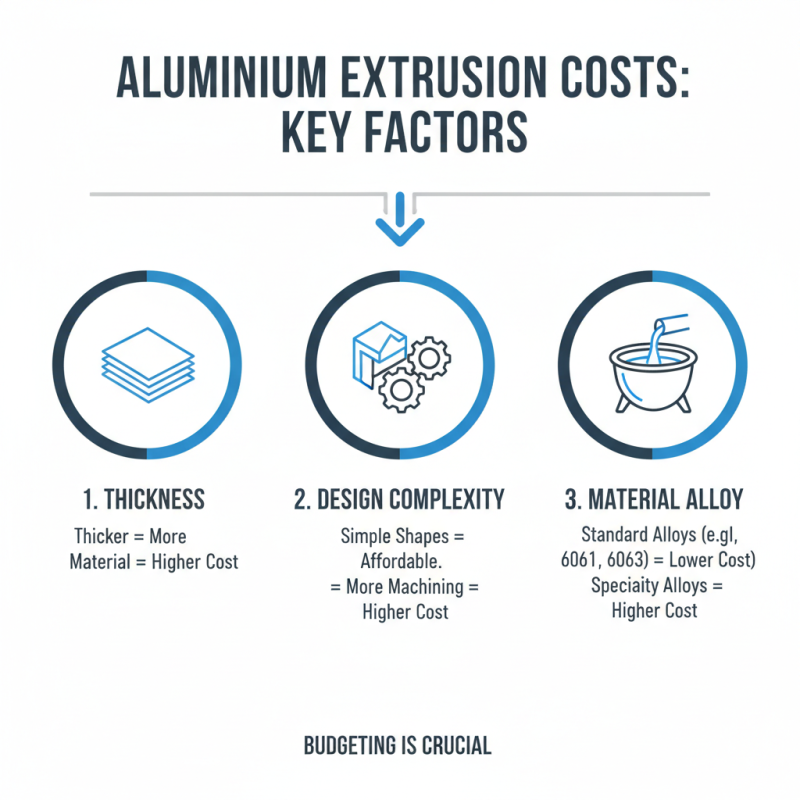

When selecting aluminium extrusions, budgeting plays a vital role. Costs can vary significantly based on several factors. The thickness and complexity of the design influence pricing greatly. Simple shapes are often more affordable. Intricate designs can lead to increased machining costs.

Shipping costs should also be factored into your budget. Consider the distance from the manufacturer to your location in NZ. Local suppliers may offer savings on transport. However, don’t rush the selection process. It’s essential to evaluate quality alongside cost. Cheap extrusions might lead to future expenses in repairs or replacements.

Evaluating your needs is crucial. What will the extrusions be used for? Heavy-duty applications may require higher quality materials. This thought could help you avoid costly mistakes. Sometimes, lower initial costs can lead to regret. It's essential to strike a balance between cost and quality to ensure the best value for your investment.

Related Posts

-

How to Choose the Best Aluminium Profile for Doors and Windows Installation

-

Ultimate Guide to Aluminium Profile Cladding Tips for Effective Installation

-

How to Choose the Right Aluminium Extrusion Grades for Your Project?

-

How to Choose Aluminium Profile Wall Cladding for Your Project?

-

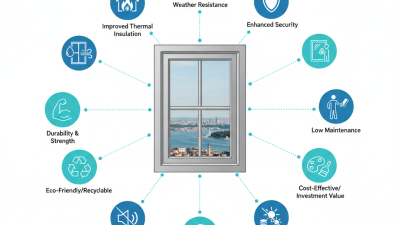

Top 10 Benefits of Choosing Aluminium Windows in Turkey for Your Home

-

2026 Top Trends in Aluminium T Slot Profile Systems What You Need to Know?